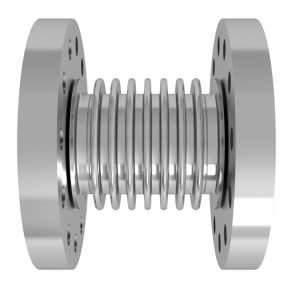

Benefits of Metal Expansion Joints

The benefits of choosing metallic expansion joints can be specified as below –

- Vibration isolation:

unnecessary vibrations in systems can damage the system as well as the surrounding equipment severely. Metal expansion joints help in isolating these vibrations, as well as dampening noise and pressure surges.

- Wide temperature ranges:

These can be used to convey fluids, solids, or abrasive media at high as well as low temperatures safely.

- Low maintenance:

By using durable and corrosion-resistant materials, metallic expansion joints require very little maintenance and have a long life cycle.High temperature and pressure resistance