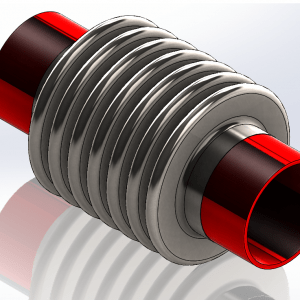

Milk and dairy hoses are common parts of modern dairy farms as they are used in milking machinery for harvesting milk from animals. They are also used in the dairy industry for conveying milk and dairy products from one part of the plant to another. These hoses are specially made to conform to FDA & EU standards to ensure proper sanitation, milk quality and to avoid chemical contamination. The hose material may include PVC (Polyvinyl Chloride), EPDM (Ethylene Propylene Diene Monomer), hybrid PVC-rubber or NBR (Nitrile Rubber). The rubber inner material makes these hoses resistant to dietary oils/fats. Usually, these hoses are reinforced with coils and an abrasion resistant outer layer to ensure longevity. Figure 1 is an example of a milk and dairy hose.

DESIGN

Milk and dairy hoses are specifically designed for transporting milk and dairy products, as well as for animal and vegetable oils and fats. When hose flexibility is important, like in a milk parlor (a cow milking area), PVC hoses are generally used. A Hybrid PVC-Rubber hose increases the temperature and pressure operating range. The temperature and pressure for the hose is dependent upon the industrial requirement, application and operating environment. Generally, the service temperature of dairy and milk hoses may vary from -40°C to 120°C (-40°F to +248°F). The tube is generally white and smooth and must comply to FDA rules. To increase durability the tubes are often reinforced with stainless steel helix wire.

MATERIAL CONSIDERATIONS

Metalic, PVC, EPDM, hybrid PVC-rubber or NBR are generally used for food grade hose materials. However, following criteria should be considered while selecting the material for milk and dairy hoses.

Sanitary union stainless steel flexible hose specification:

1 Hose material: SS304 or 316L

2 Braided mesh material: SS304

3 Hose size: 1/4INCH – 8 INCH

4 Hose type: annular or spiral corrugated

5 Connection type: SMS sanitary grade union

6 Union fittings material: SS304 or SS316L

7 Maximum working pressure: 1.6Mpa

8 Working temperature range: -200℃ ~ +500℃

9 Union standard: SMS (RJT, DIN, T thread also available)

10 Hose overall length: 0.2-20m or as per your request

Sanitary union stainless steel flexible hose advantages:

Corrosion resistance

High temperature resistance

Low temperature resistance

Light weight, small size,good flexibility.

Sanitary union stainless steel flexible hose application:

Food industry

Edible oil industry

Chemical industry

Medical industry

Dairy industry

Toothpaste factory

Wine-making industry

Vinegar factory

Heating and ventilation etc