Milk and dairy hose

Material considerations

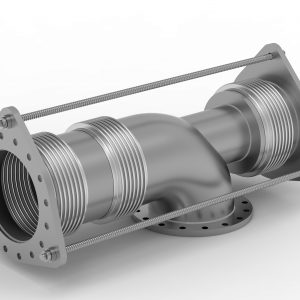

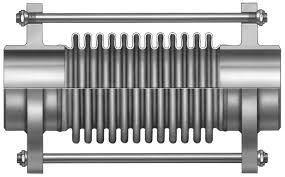

Stainless-steel wire reinforced hose

Figure 2: Stainless-steel wire reinforced hose

PVC, EPDM, hybrid PVC-rubber or NBR are generally used for food grade hose materials. However, following criteria should be considered while selecting the material for milk and dairy hoses.

Phthalates-free: Phthalates are a group of chemicals that make plastic harder to break and flexible. The main concern in the dairy industry is that phthalates can escape into fatty foods when it comes in contact with plastic and rubber equipment. To ensure that phthalates don’t contaminate the media within the hose, good solutions are phthalates-free plasticizers, silicones or advanced synthetic rubbers.

Food grade hoses: Dairy hoses must be a food grade hose that are made from non-toxic compounds that prevent harmful chemical reactions. They are also odorless and tasteless, which help in preserving the actual order & taste of the milk & dairy product.

Non-metal hoses: Dairy hoses should be non-metal hoses to prevent contamination from rust and corrosion. PVC or rubber materials are used, which not only prevents the problem of contaminations, but also provides high flexibility. To ensure strength and durability of the hose, helical structured stainless-steel wires are used in these hoses. Figure 2 is an example of stainless-steel wire reinforced hose.

Flexibility: Flexibility is important for milk and dairy hoses as they are attached to the milking machine cluster, or milking unit, in the milking parlor.