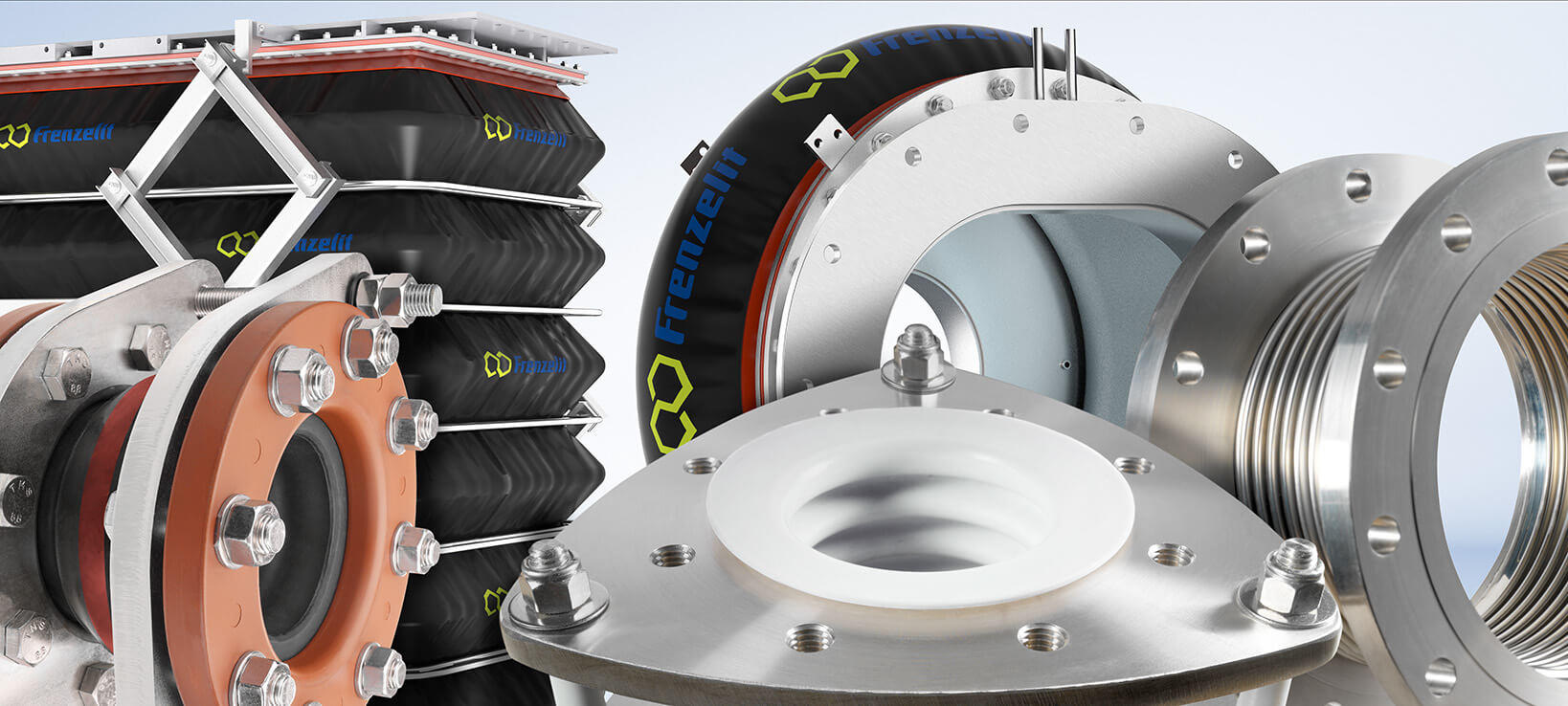

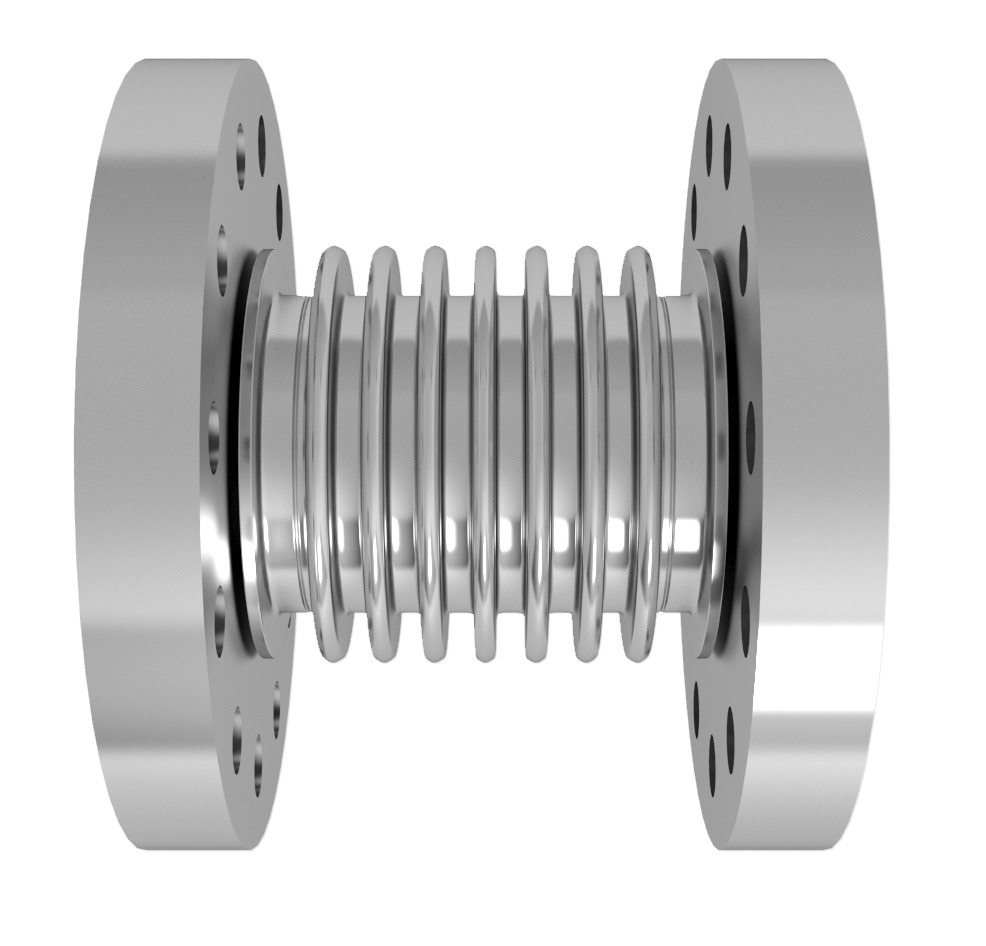

Metallic & Rubber expansion joints use bellows to convey high temperature and pressure substances in pipelines and ducts. Since most industries today deal with pipelines carrying materials of high temperature and pressure, thermal expansion is common. This effect can cause mechanical deformation and vibrations which can eventually cause cracks, leakages, and even failure of the entire system. To avoid this from happening, expansion joints are used. They accommodate these changes by acting as a bridge and expanding and contracting according to the conditions. The contain movements in the axial direction, lateral, angular, as well as universal direction depending on the type of expansion joint used.

Bellows expansion joints, also known as compensators are produced by first manufacturing the bellows and then attaching the necessary liners, control rods, end fittings, and other components to it. As per the requirement of the target location and function, these are designed in various shapes and sizes. The metal expansion joints are used in petrochemical, oil and gas industry, automobile industry, nuclear plants, and so on.

APPLICATION AREAS OF EXPANSION JOINTS

• Heating and cooling devices

• Materials handling technologies

• Water pipes

• Desalination plants

• Compressors

• Blowers and fans

• Cement industry

• Chemical industry

• Glass industy

• Wood-processing industry

• Pulp and paper industry

• Railed vehicles

• Refineries

• Shipbuilding

• Steel mills

• Sugar industry