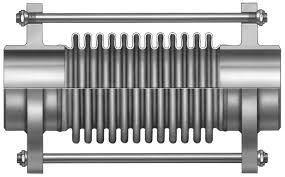

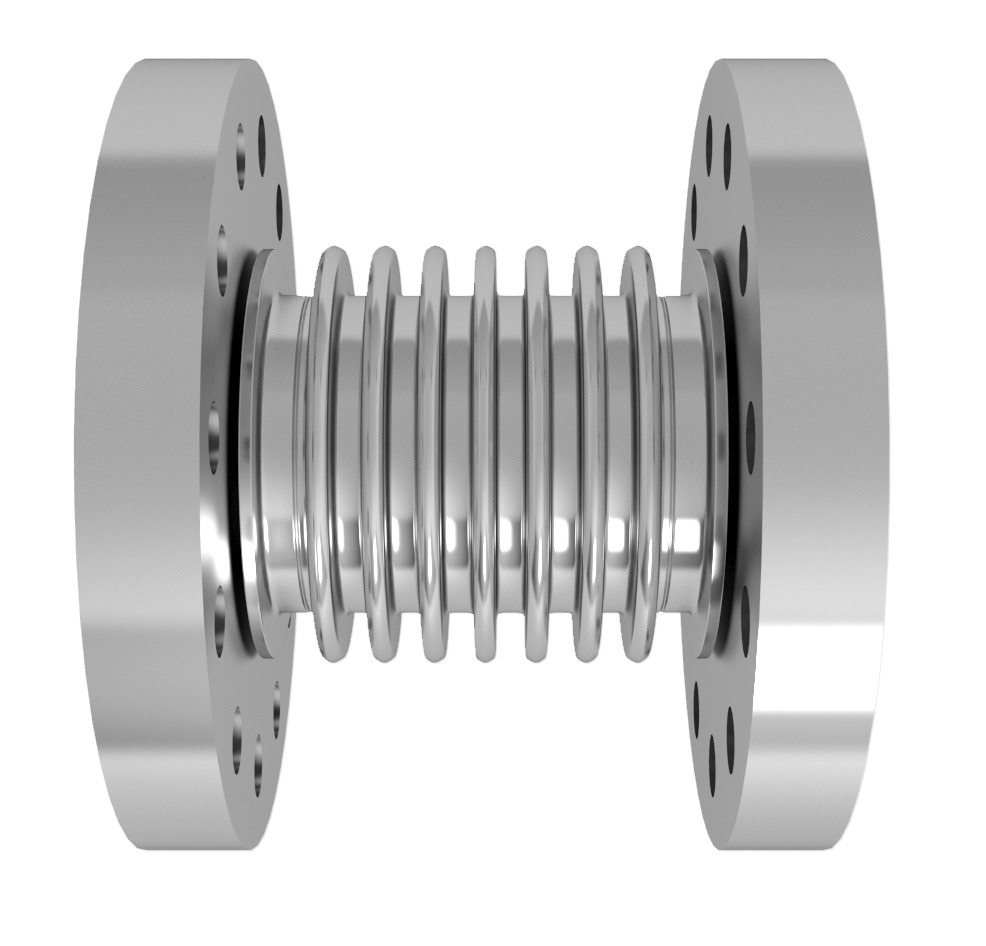

- Single Expansion Joints

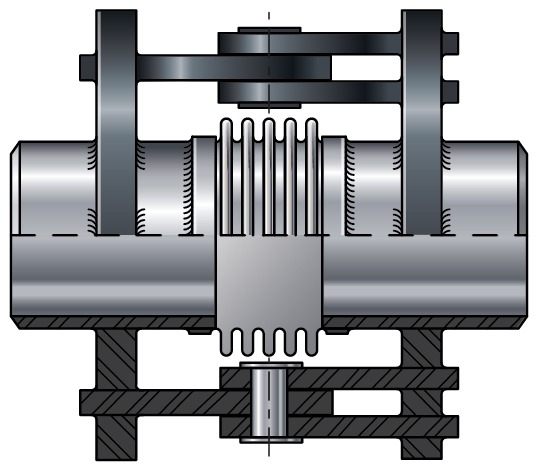

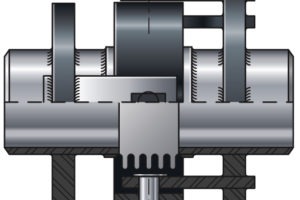

- Hinged Expansion Joints

- Gimbal Expansion Joints

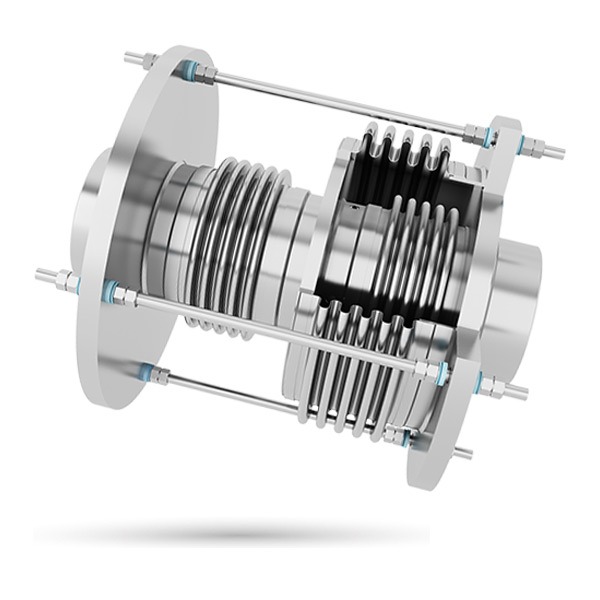

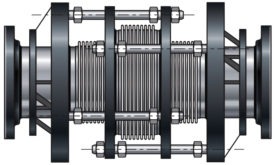

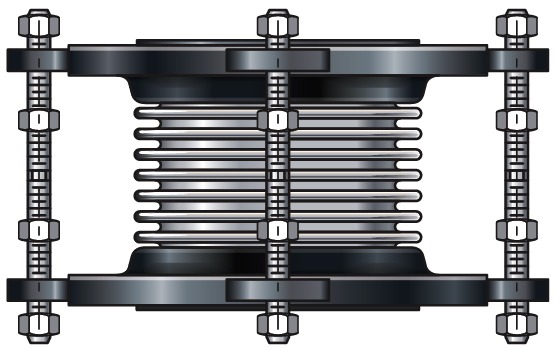

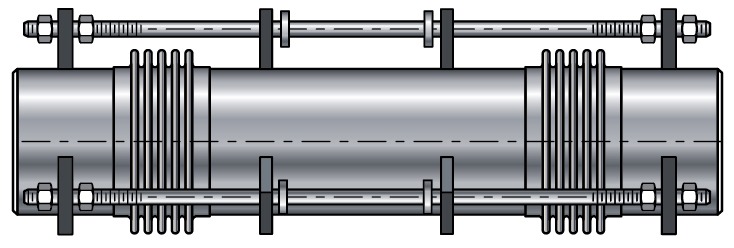

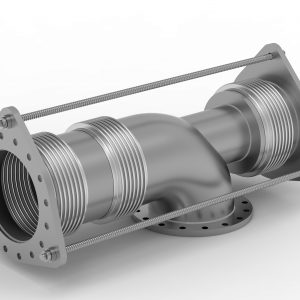

- Universal Expansion Joints

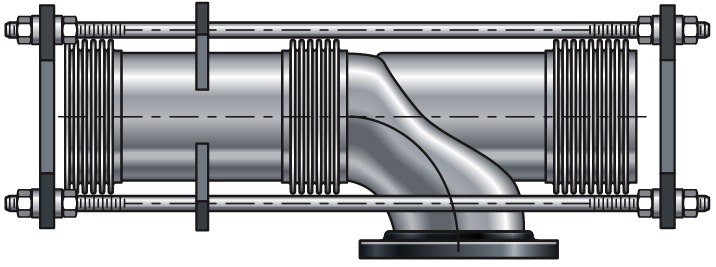

- Elbow Pressure Balanced Expansion Joints

- In-line Pressure Balanced Expansion Joints

- Externally Pressurized Expansion Joints

- Toroidal Expansion Joints

- Thick Wall Expansion Joints

- Slip-type Expansion Joints

- Rectangular Metallic Expansion Joints

- Refractory Lined Expansion Joints

- Fabric Expansion Joints

- Rubber Expansion Joints and Bellows

TYPES OF EXPANSION JOINTS AND BELLOWS

Some advantages of installing Pipeline Expansion Joints:

- Simple in design and function.

- Space reduction.

- Weight reduction.

- Cost reduction.

- Reduce engineering and design complexity to piping systems.

- Better flexibility for piping layout.

- Reliable and proven in the field.

It is also known as a movement joint, which is an assembly consisting of separation in the wall a flexible material like a bond breaker or sealant. Bond breaker materials may comprise of sprays, liquids, rods, or tapes. They are required for breaking the bond between building sections for ensuring the sections can separate. The material being compressible, it can accommodate the movement of adjacent materials. For closing the joint opening and mitigating moisture from entering the joint, a flexible sealant is applied along with accommodating movement between wall sections. When performing a building envelope survey, all of these factors must be taken into account.