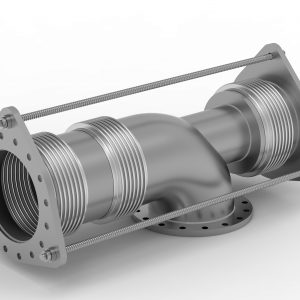

Metal pipe expansion joints have a variety of applications in the power, petrochemical, refining, chemical, and steel industries. Like circular pipe expansion joints, rectangular pipe expansion joints absorb three types of movement: axial, lateral and angular. For the purpose of designing rectangular bellows, it is critical to know in which direction the lateral and angular movements will occur, i.e. parallel to the long and/or short side of the bellows. Unlike circular bellows where the pressure stress is a circumferential membrane (hoop) stress, the rectangular bellows must be designed for longitudinal (beam) bending stresses.

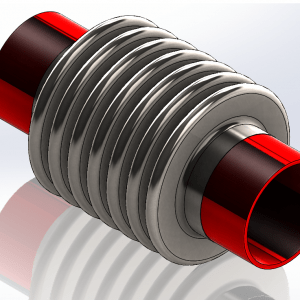

Expansion joints are typically used in Fluid Catalytic Cracking Units (FCCU), furnaces, hot gas turbines, styrene plants, fluidized bed boilers, kilns, power recovery trains, and thermal oxidizers. For hot applications (up to 1400°F), the bellows are packed with KO wool and lined with insulating refractory. Refractory lining can reduce the pipe wall temperature to 300-450°F and also protect the bellows from abrasion caused by the flow of abrasive particles.